Among EXAIR's comprehensive line of Intelligent Compressed Air

Products, the Vortex Tube

stands out as a unique, and fascinating, solution for a variety of

applications requiring a flow of cold air:

·

Cabinet Cooler Systems:

clean, cold air to protect electrical and electronic components housed in an

enclosure. Installs in minutes; no moving parts; reliable &

maintenance free.

·

Cold Gun Aircoolant Systems:

Direct, focused flow of cold air to replace messy coolant in machining,

cutting, drilling, grinding, etc., applications. Integral magnet base

for quick & easy installation; single or dual outlet hose kits; standard

or High Power to meet any need. Optimized flow for maximum cooling and

freeze prevention.

·

Adjustable Spot Cooler:

Similar to the Cold Guns in many ways, but with variable performance for

specific applications. Cold air to -30°F (-34°C) on demand.

·

Mini Cooler: Similar to the Cold Guns

and Adjustable Spot Coolers - magnetic base mounting and single or dual

outlet hose kits, but more compact. Lower flows for smaller jobs.

Then there are the Vortex Tubes themselves...at the heart of

all of these products, but perfectly capable all on their own. In fact,

in certain situations, "plain old" Vortex Tubes have been used to

do the exact same jobs as all of the above products. They can even be

customized, in and of themselves, to meet specific installation, operation,

and/or performance needs:

·

High Temperatures: It should come as no surprise that cold

air is often needed because a heat-sensitive item is located in a high heat

environment.

o Vortex Tubes come standard with plastic

Generators and Buna o-rings, which are good for ambient temperatures up to

125°F (52°C).

o High Temperature Vortex Tubes are fitted

with brass Generators and Viton o-rings for environments where the

temperature can reach 200°F (93°C).

·

Preset temperature & flow: Many times, the ability to adjust the

performance of a Vortex Tube is a big benefit, but occasionally it's a

liability.

o I know none of your co-workers are like this

(nor are mine) but I've heard of people who think they "know

better" and are prone to tampering with something that is (or WAS)

working just fine, thank you very much.

o Perhaps you actually DO know better, through

experimentation and experience, the optimal performance setting for your

application. Let's say, for example, you install Vortex Tubes on a line

of your products, and a technician has to "dial it in" to a

specific Cold Fraction.

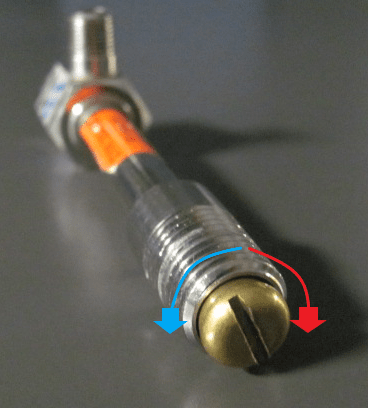

o Any Vortex Tube can be fitted with a drilled

orifice (or "Hot Plug") to replace the Hot Valve, which

presets performance to a specific, non-adjustable value. If you know

the Cold Fraction you need, it's as easy as that. If not, it's as easy

as getting a stock Vortex Tube, setting the Cold Fraction where you want it,

securing the Hot Valve in position (piece of tape works just fine,) and

sending it in.

|

Comentários

Enviar um comentário