Controlling Temperature and Flow in a Vortex Tube

by bsbergmann

|

A few weeks ago, we looked at the Vortex Tube and provided a

general overview of the device (see that blog here.) In a nutshell - a Vortex Tube uses

an ordinary supply of compressed air as a power source, creating two streams of

air, one hot and one cold – resulting in a low cost, reliable, maintenance free

source of cold air for spot cooling solutions.

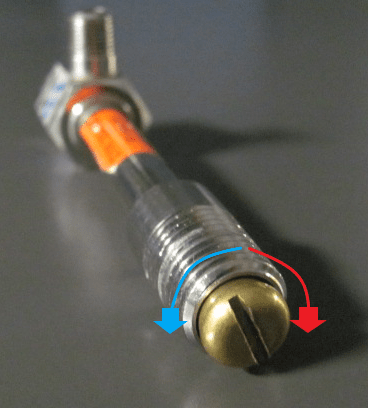

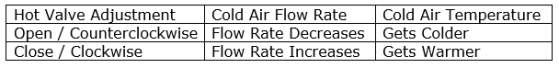

One of the features of the Vortex Tube is that the temperature

of the cold air and the cold air flow rate is changeable. The cold air flow and

temperature are easily controlled by adjusting the slotted valve

in the hot air outlet.

Opening the valve (turning it counterclockwise) reduces the cold

air flow rate and the lowers the cold air temperature. Closing the valve

(turning it clockwise) increases the cold air flow and raises the cold air

temperature.

As with anything, there is a trade off - to get higher a cold

air flow rate, a moderate cold air temperature is achieved, and to get a very

cold air temperature, a moderate air flow rate is achieved.

An important term to know and understand is Cold Fraction, which

is the percentage of the compressed air used by the Vortex Tube that is

discharged through the Cold End. In most applications, a Cold Fraction of

80% produces a combination of cold flow rate and and cold air temperature that

results in the maximum refrigeration or cooling output form a Vortex Tube.

For most industrial applications - such as process cooling, part

cooling, and chamber cooling, maximum refrigeration is best and the 32XX series

of Vortex Tubes are preferred. For those applications where 'cryogenic'

cooling is needed, such as cooling lab samples, or circuit testing, the 34XX

series of Vortex Tube is best.

To set a Vortex Tube to a specific temperature, simply insert a

thermometer into the cold air exhaust and adjust the hot valve. Maximum

refrigeration, at 80% Cold Fraction, is achieved when the cold air temperature

drop is 50°F (28°C) from the incoming compressed air temperature. See the video

posted here for

measuring and lowering and the cold air temperature.

For those cases when you may be unsure of the required cold air

flow rate and cold air temperature to provide the needed cooling in an

application, we would recommend an EXAIR Cooling Kit.

The Cooling Kit contains a Vortex Tube, Cold Air Muffler, Air Line Filter, and

a set of Generators that will allow for experimentation of the full range of

air flows and temperatures possible.

To discuss your application and how a Vortex Tube or any EXAIR Intelligent Compressed Air Product can

improve your process, feel free to contact EXAIR, myself, or one of our other

Application Engineers. We can help you determine the best solution!

Contact: José Garcia

Tel: 351 932308640

Comentários

Enviar um comentário