A few weeks ago, we posted a blog discussing

how artificial demand and leaks can lead to poor performance and expensive

waste. Today, I'd like to review how following a few simple steps can

help optimize your current compressed air system and reduce compressed air

usage.

The first step

you want to consider is measuring the air usage in the system. To do this,

you want to start at the compressor and check individual leads to each drop

point to a blowoff device, record your findings to track the demand. By

measuring your compressed air usage, you can locate the source of high usage

areas and monitor the usage on each leg of the system. If the demand exceeds

the supply, there is potential for problems to arise, such as lowered

pressure and force from compressed air operated devices leading to irregular

performance.

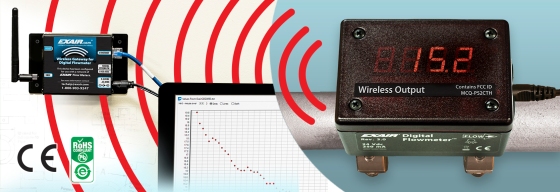

EXAIR’s Digital Flowmeters are designed to

measure flow continuously and accurately to give you real-time flow

measurements of your compressed air system to help identify problems areas.

Step 2 is

to locate the source of waste. Again, compressed air leaks can result in a

waste of up to 30% of a facility’s compressor output. A compressed air leak

detection and repair program can save a facility this wasted air.

Implementing such a program can be used as a way for a facility to “find”

additional air compressor capacity for new projects. Whenever a leak occurs,

it will generate an ultrasonic noise.

Our Ultrasonic Leak Detector is designed to

locate the source of ultrasonic sound emissions up to 20’ away. These

ultrasonic sound emissions are converted to a range that can be heard by

humans. The sound is 32 times lower in frequency than the sound being

received, making the inaudible leaks, audible through the included headphones

and the LED display gives a visual representation of the leak.

The 3rd step

involves finding the source of noisy and wasteful blowoffs, like open pipes

or homemade blowoffs, and replacing them with an energy efficient, engineered

solution. By replacing these devices, you are not only reducing the amount of

waste but also improving operator safety by complying with OSHA safety

requirements.

EXAIR’s Digital Sound Level Meter is an easy to

use instrument that measures and monitors the sound level pressure in a wide

variety of industrial environments. The source of loud noises can be quickly

identified so that corrective measures can be taken to keep sound levels at

or below OSHA maximum allowable exposure limits.

The easiest way to reduce compressed air usage and save on

operating expense is to turn off the compressed air to a device when it isn’t

needed, step 4

in the process. Not only will this save money, in many cases, it can also

simplify a process for the operator.

A simple manual ball valve and a responsible

operator can provide savings at every opportunity to shut down the air

flow.

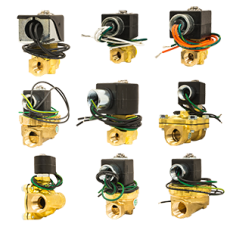

For automated solutions, a solenoid valve can

be operated from a machine’s control. For example, if the machine is off, or

a conveyor has stopped – close the solenoid valve and save the air.

A foot pedal valve offers a hands free solution

to activate an air operated device only when needed, such as being

implemented in an operator’s work station.

For even more control, you can use a device like our EFC or

Electronic Flow Control. This helps minimize compressed air usage by

incorporating a programmable timing controlled (0.10 seconds to 120 hours)

photoelectric sensor to turn off the compressed air supply when there are no

parts present. It is suited for NEMA 4 environments and can be easily wired

for 100-240VAC.

Step 5,

intermediate storage. Some applications require an intermittent demand for a

high volume of compressed air. By installing a receiver tank near the point

of high demand, there is an additional supply of compressed air available for

a short duration. This will help eliminate fluctuations in pressure and

volume.

EXAIR offers a 60 gallon, ASME approved vertical steel tank

with mounting feet for easy installation near high demand processes.

Many pneumatic product manufacturers have a certain set of

specifications regarding performance at stated input pressures. In many

applications, or in the case of using a homemade blowoff device like open

pipe, these wouldn’t necessarily require the full rated performance of the

device or full line pressure. Controlling the air pressure at the

point-of-use device will help to minimize air consumption and waste, step 6.

By simply installing a pressure regulator

on the supply side, you can start off at a low pressure setting and increase

the pressure until the desired result is achieved. Not only will this help to

conserve energy by only using the amount of air required for the application,

it also allows you to fine tune the performance of the point-of-use device to

match the application requirements.

If you have any questions, please contact

an application engineer at + 351 932308640.

|

Comentários

Enviar um comentário