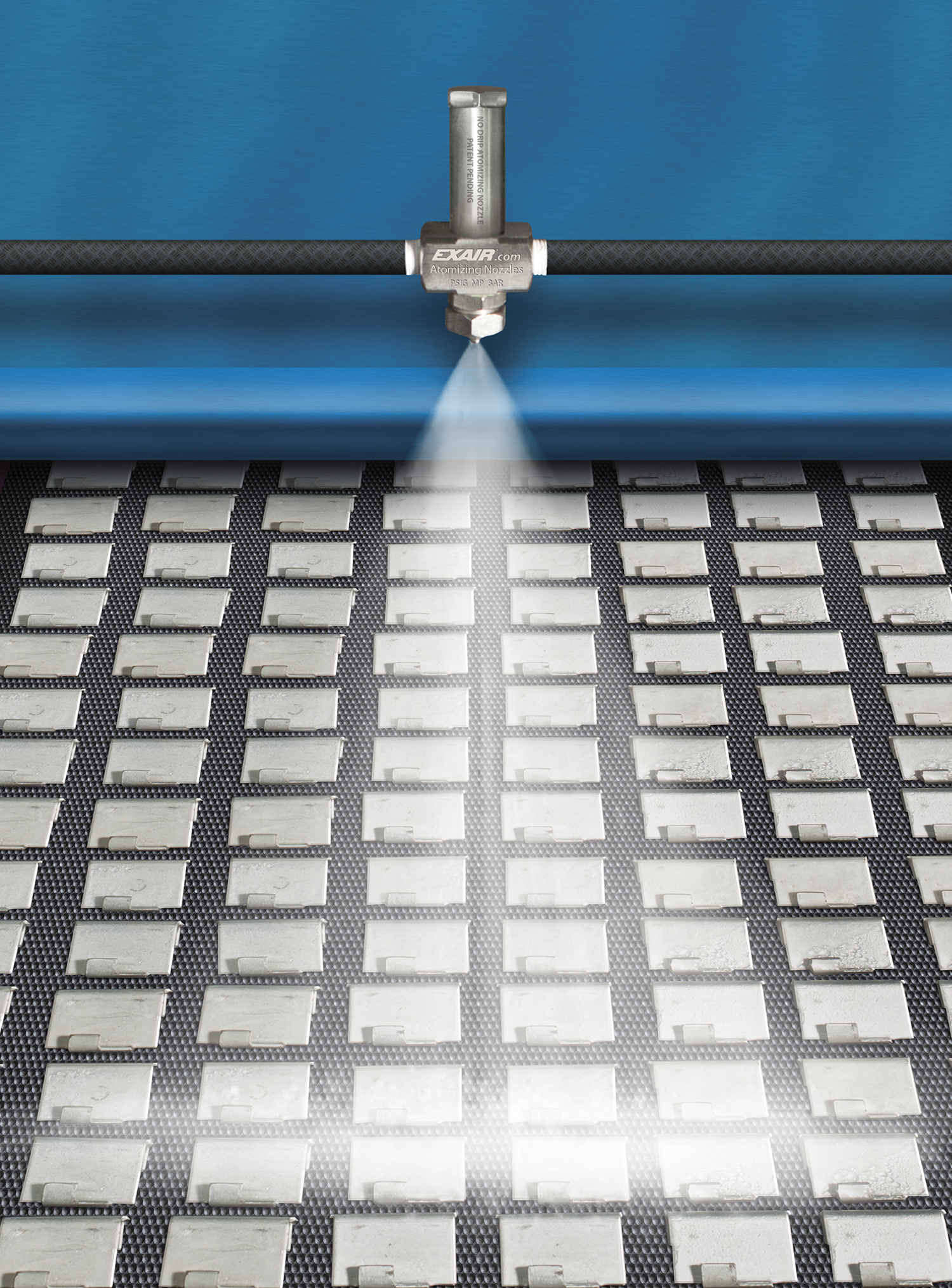

No Drip Internal Mix Atomizing Nozzles

by bsbergmann

|

Eliminate drips to conserve valuable

liquids and improve product finishes! EXAIR's patented No Drip Atomizing Nozzle

provides the same great performance as the the standard atomizing nozzles with

the added benefit of positive liquid flow stoppage when the compressed air is

shut off.

The No Drip option eliminates the

occurrence of post spray liquid flow that results in unwanted drips that can

mar a finish on painted or coated surfaces. Also, excess liquid loss is

minimized saving on expensive materials like chemicals or coatings. When

the compressed air is shut-off, the No Drip nozzle positively seals off the

flow, eliminating the chance for a drip or lost liquid. Only one compressed air

line is needed, as the line to combine and atomize the liquid also provides the

no drip operation and control.

The No Drip Atomizing Nozzles are

available in (3) types - Internal Mix, External Mix, and

Siphon Fed.

The Internal Mix type operates under

the principle that the air and liquid come together and mix 'internal' to the

nozzle. This type provides the finest atomization and smallest droplet

size. The Internal Mix type of nozzle can be used with liquids up to 300 cP in

viscosity. Both the air and liquid sides are pressure fed. The No

drip Internal Mix Atomizing Nozzles are best for pressure fed applications not

requiring independent air and liquid control.

The No Drip Atomizing Nozzles

are available in (3) sizes - 1/8, 1/4, and 1/2 NPT - to provide a wide range of

flow rates and pattern sizes. The No Drip feature does not impact the

flow rates compared to the standard models. Minimum air pressure

operation is 30 PSIG for the 1/4 and 1/2 NPT, and just 20 PSIG for the 1/8 NPT

models.

Like the standard Internal Mix

Atomizing Nozzles, spray patterns include narrow and wide angle round,

flat fan, deflected flat fan and a 360° hollow circular pattern offering a wide

selection to best meet the application needs.

Operation at up to 180 spray cycles

per minute is possible. Air and Liquid Caps can be switched out to change

the pattern and flow rates.

Typical Applications

·

Painting

·

Coating

·

Rinsing

·

Cooling

·

Quenching

·

Wetting

·

Humidification

·

Dust Control

Advantages

·

No post spray drip

·

Adjustable

·

Easily used with EFC

·

Minimizes air and liquid consumption

·

All stainless steel construction

·

Fine atomization

·

Interchangeable liquid and air caps

·

Compact

If you need an Atomizing Spray Nozzle

or any of the EXAIR Intelligent Compressed Air®

Products, feel free to contact EXAIR and

myself or one of our Application Engineers can help

you determine the best solution.

Tecmer,Lda

Tel:+351932308640

Email:j.araujo@tecmer.pt

Comentários

Enviar um comentário