I recently had a chat conversation

with a customer who was looking to cool the tooling on his CNC router, mill

and lathe in his small machine shop. During the machining process, as the

tooling would begin to heat up, it would warp the bit, causing irregularities

in the finished product. In some cases the tooling was getting so hot, it

would actually break, creating a safety concern.

He had reviewed some of our cooling products and was thinking

of using our Cold Gun in the application but was

concerned with the air demand. The Cold Gun

consumes 15 SCFM @ 100 PSIG and provides a 50°F temperature drop (from supply

temperature) with 1,000 Btu/hr. of cooling capacity. The problem was that his

compressor only produces a little over 9 SCFM. I explained that the existing

compressor would in fact be undersized as it doesn't produce enough

volume to keep up with the demand of the Cold Gun.

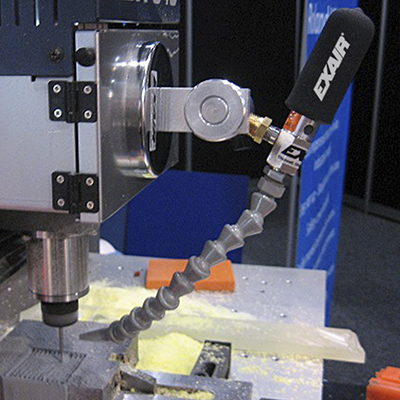

Due to the limited amount of compressed air available, our Mini

Cooler System, Model # 3808, would be the better solution. The

Mini

Cooler also provides a 50°F temperature drop with a little

less cooling power, 550 Btu/hr., but this system only requires 8 SCFM @

100 PSIG, falling within the existing compressor's output capacity. The Mini

Cooler also includes a magnetic base as well as flexible

tubing to direct the cold air to the desired location, making it easy to move

from machine to machine.

If you are considering an EXAIR product

for an application or have additional questions about performance, contact

an application engineer for assistance in making the best selection.

José Garcia Araújo

Application Engineer j.araujo@tecmer.pt.pt

jsnicholl | February 26, 2018

at 9:03 AM | Tags: 3808, @EXAIR_JN,

cold

air gun, Cold Gun, cold gun aircoolant, coolant

system, cutter grinding, cutting

fluid, drill grinding, Dry

machining, exair, exair

cold gun, jsnicholl, live

chat, machining plastic, Mini

Cooler, mist coolant, online

chat, small air compressor, small part cooling, small

parts, surface grinding, tire

grinding, tool cooling, tool

sharpening | Categories: Cold Gun | URL: https://wp.me/phlkn-8HX

|

Comentários

Enviar um comentário