A sheet metal company made thin stainless steel sheets in

their process. Before the sheets were rolled up, it went through

a washing system. Two blower-type air knives were mounted after the

wash cycle to remove the residual water from the surface. They

purchased the blower-style air knives under the belief that they would save

money by not using compressed air. They found out quickly that it was

not a true statement especially when it comes to the total cost of ownership.

With the dirty environment at their facility, the inlet filter

on the blower was getting plugged. The blower motor would heat up from

the filter being restricted. After eight months of service, the blower

motor failed due to excessive heat. The replacement was very costly,

and it created a production stoppage for an entire day. The

manufacturer of the blower-type air knife recommended that the filter should

be changed every month instead of quarterly. This recommendation

increased the monthly budget for the blower system, but they did not want to

replace the blower motor again. Instead of a quarterly stop in

production for maintenance, the washing system had to be stopped every month

for filter change-out. They decided to contact EXAIR to see if

their concept of “saving money” with the blower-type air knife was valid.

To better explain the concept, I divided the comparisons into

different categories explaining the details between the Super Air Knife

and the blower system.

1.

Initial

Cost:

o Blower System – They are an expensive set up when you

have to include a blower, ducting, and a knife. To have any flexibility, a

control panel with a VFD will be needed.

o Super Air Knife – It is a fraction of the cost. With their

system above, we were roughly 1/4 the cost. A capital expense would not

be required for ordering two Super Air Knives to remove the water from the

stainless steel sheets.

2.

Maintenance:

o Blower System – The intake filter had to be changed every

month, and the customer estimated a cost of $150.00 each. The motor and belt

also had to be checked quarterly as a preventive maintenance. Being

that the blower motor is a mechanical device, the bearings and belts will

wear and have to be replaced. Without proper maintenance, things can

break prematurely. This customer had to already replace the motor in

their system.

o Super Air Knife – They do not have any moving parts to wear

out, and they are not affected by the dirty environment. Only compressed air

is needed to operate. The maintenance requirement is to change the

compressed air filter once a year. The annual price for the replacement

filter is less than $35.00.

3.

Compressed

air usage:

o Blower System – This device does not require any

compressed air to operate, but it does use an electric motor. For this

customer, they had a 7.5KW blower motor. With the inherent designs of

blower-type air knives, they have reduced blowing forces and turbulent air

flows. This combination required maximum power output on the 7.5KW

blower motor.

o Super Air Knife –With their unique design, it has one of

the highest efficiencies in the market place. It can entrain 40 parts of

ambient “free” air with every 1 part of compressed air. With laminar

flow and the power of compressed air, the Super Air Knives can be used at a

much lower air pressure. To compare with the electric blower motor

above, the Super Air Knives only required 11KW of compressor power to

operate.

4.

Noise:

o Blower System – With the turbulent air flow, the blower

units are very loud. It can have a sound level near 93 dBA. If

operators are working near the system, they would require PPE for

hearing. The cost for proper hearing equipment and the training for the

operators will add more cost with using blower systems.

o Super Air Knife – These units are very quiet. Even at an

elevated pressure, the sound level is only 72 dBA at 100 PSIG. This

level is below the maximum noise exposure for hearing safety as marked in

OSHA 29CFR 1910.95(a).

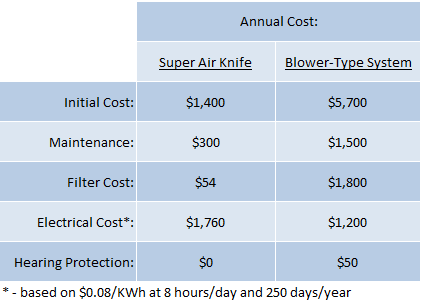

I tabulated the annual cost comparison and shared it with the

customer to better explain the total cost of ownership. After reviewing

the information, they decided to try two pieces of the model 110230 Super Air Knife Kits.

When they replaced the blower-type air knives, the customer did share some

additional information. First, they were amazed at the ease of

installation. The blower-type air knives had to be electrically wired;

floor space was sacrificed for the blower; the connection hoses were large

and bulky; and the mounting was cumbersome. The customer also noticed

the amount of power that was created by the Super Air Knives. They were

able to increase the feed rates of the stainless steel sheets if they wanted

and still keep the surface dry. This gave them flexibility in their

production system. And of course, the maintenance time and cost were

practically eliminated. Compressed air is expensive, but if you use

EXAIR products, you can use the compressed air very efficiently. As

noticed in the tabulation above, the total cost of ownership is very

expensive for the blower-type air knives as compared to the Super Air

Knives.

Distribuidor em Portugal :

Tecmer,Lda

Contacto: José Garcia Araújo

Tel:+351 932308640 /+351 2523173124

Email:geral@tecmer.pt

www.tecmer.pt

|

Comentários

Enviar um comentário