Compressed air is used to operate pneumatic systems in a

facility, and it can be segregated into three sections; the supply side, the

demand side, and the distribution system. The supply side is the air

compressor, after-cooler, dryer, and receiver tank that produce and treat the

compressed air. They are generally located in a compressor room

somewhere in the corner of the plant.

The demand side are the

collection of end-use devices that will use the compressed air to do

“work”. These pneumatic components are generally scattered throughout

the facility. To connect the supply side to the demand side, a

compressed air distribution system is required. Distribution systems

are pipes which carry the compressed air from the compressor to the pneumatic

devices. For a sound compressed air system, the three sections have to

work together to make an effective and efficient system.

An analogy, I like to compare to the compressed air system, is

an electrical system. The air compressor will be considered the voltage

source, and the pneumatic devices will be marked as light bulbs. To

connect the light bulbs to the voltage source, electrical wires are

needed. The distribution system will represent the electrical

wires. If the wire gauge is too small to supply the light bulbs, the

wire will heat up and the voltage will drop. This heat is given off as

wasted energy, and the light bulbs will dim.

The same thing happens within a compressed air system.

If the piping size is too small, a pressure drop will occur. This is

also wasted energy. In both types of systems, wasted energy is

wasted money. One of the largest systematic problems with compressed

air systems is pressure drop. If too large of a pressure loss occurs,

the pneumatic equipment will not have enough power to operate

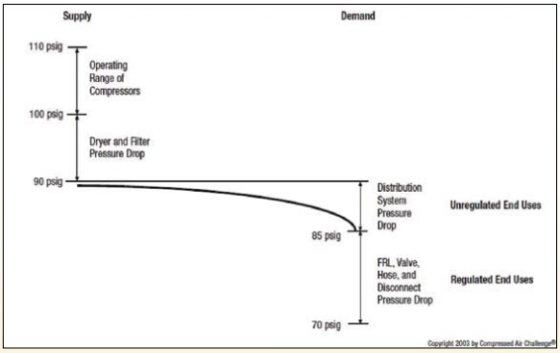

effectively. As shown in the illustration below, you can see how the

pressure decreases from the supply side to the demand side. With a

properly designed distribution system, energy can be saved, and in reference

to my analogy, it will keep the lights on.

To optimize the compressed air system, we need to reduce the

amount of wasted energy; pressure drop. Pressure drop is based on

restrictions, obstructions, and piping surface. If we evaluate each

one, a properly designed distribution system can limit the unnecessary

problems that can rob the “power” from your pneumatic equipment.

1.

Restriction:

This is the most common type of pressure drop. The air flow is forced into

small areas, causing high velocities. The high velocity creates

turbulent flow which increases the losses in air pressure. Flow within

the pipe is directly related to the velocity times the square of the

diameter. So, if you cut the I.D. of the pipe by one-half, the flow

rating will be reduced to 25% of the original rating; or the velocity will

increase by four times. Restriction can come in different forms like

small diameter pipes or tubing; restrictive fittings like quick disconnects

and needle valves, and undersized filters and regulators.

2.

Obstruction:

This is generally caused by the type of fittings that are used. To help

reduce additional pressure drops use sweeping elbows and 45-degree fittings

instead of 90 deg. elbows. Another option is to use full flow ball

valves and butterfly valves instead of seated valves and needle valves.

If a blocking valve or cap is used for future expansion, try and extend the

pipe an additional 10 times the diameter of the pipe to help remove any

turbulence caused from air flow disruptions. Removing sharp turns and

abrupt stops will keep the velocity in a more laminar state.

3.

Roughness:

With long runs of pipe, the piping surface can affect the compressed air

stream. As an example, carbon steel piping has a relative rough

texture. But, over time, the surface will start to rust creating even a

rougher surface. This roughness will restrain the flow, creating the

pressure to drop. Aluminum and stainless steel tubing have much

smoother surfaces and are not as susceptible to pressure drops caused by

roughness or corrosion.

As a rule, air velocities will determine the correct pipe

size. It is beneficial to oversize the pipe to accommodate for any

expansions in the future. For header pipes, the velocities should not

be more than 20 feet/min (6 meter/min). For the distribution lines, the

velocities should not exceed 30 feet/min (9 meter/min). In following

these simple rules, the distribution system can effectively supply the

necessary compressed air from the supply side to the demand side.

To have a properly designed distribution system, the pressure

drop should be less than 10% from the reservoir tank to the

point-of-use.

By following the tips above, you can reach that goal and

have the supply side, demand side, and distribution system working at peak

efficiency. If you would like to reduce waste even more, EXAIR offers a

variety of efficient, safe, and effective compressed air products to fit

within the demand side. This would be the pneumatic equivalent of

changing those light bulbs at the point-of-use into LEDs.

Distribuidor em Portugal

Tecmer,Lda Tel: +351 932308640

Email:geral@tecmer.pt

|

Comentários

Enviar um comentário