Beer Brewers Use Assured Automation G2 Series Flow Meters to Maintain Consistent Quality

A craft brewery was looking for a meter to accurately measure hot water as it goes into a mash tank. The meter will also be used to measure chemicals during the cleaning process.

The staff was looking for a versatile meter that would be easy to install in-line, included an easy-to-read display and could be mounted in different orientations depending on piping layouts.

Solution:

G2 Series Flow Meters

Application:

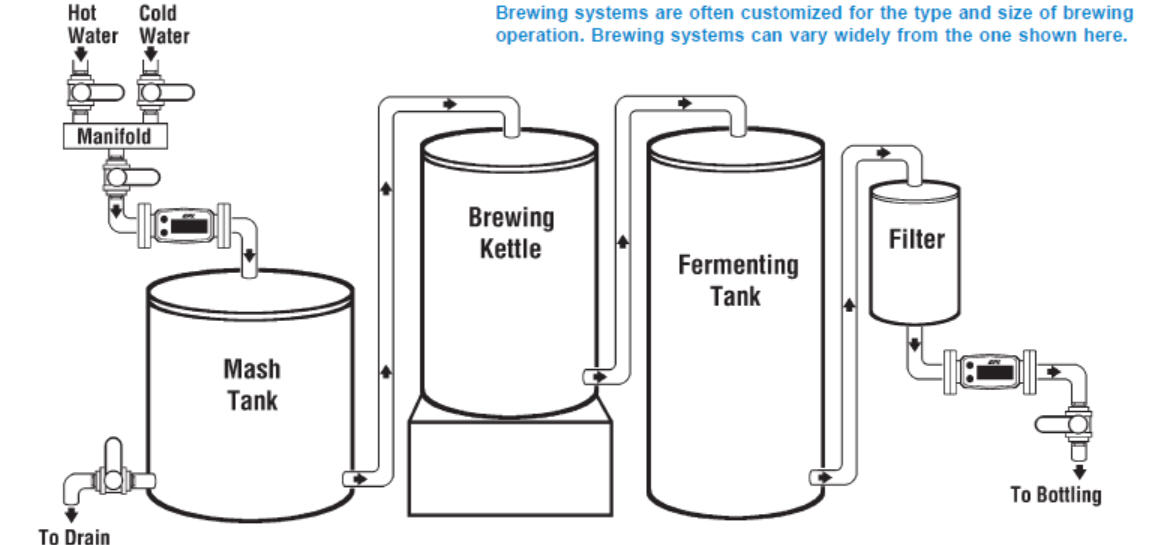

The beer brewing industry is a huge, global business including home brewing operations, thousands of smaller producers and a handful of major companies. Customers report that using Assured Automation Meters improves the quality of beer by making each batch consistent. Brewing systems can differ depending on the size of tanks and the needs of the customer.

The staff was looking for a versatile meter that would be easy to install in-line, included an easy-to-read display and could be mounted in different orientations depending on piping layouts.

Solution:

The brewer called us and was given the recommendation of the G2 Stainless Steel Liquid Flow Meter. This meter offered excellent fluid compatibility in the brewing process and later during cleaning.

A second meter was needed before the bottling process. Price can be a factor when using multiple meters but the Assured Automation meters proved to be cost effective.

Assured Automation’s G2 industrial grade flow meters can be removed easily, making equipment cleaning simple. The internal parts can be replaced on-site reducing down time, making maintenance simple.

G2 Series Flow Meters

- Accurate and reliable

- Battery operated

- Compact design

- Self-contained

- Not dependent on mounting orientation

- Digital Readout

- Easy to clean

Application:

The beer brewing industry is a huge, global business including home brewing operations, thousands of smaller producers and a handful of major companies. Customers report that using Assured Automation Meters improves the quality of beer by making each batch consistent. Brewing systems can differ depending on the size of tanks and the needs of the customer.

Comentários

Enviar um comentário