The process of making cocoa powder and chocolate products is fascinating to say the least. The video above shows the process at the Hershey factory in a throwback “How Its Made” video from the 70’s. (I think; based on the hairstyles. Also based on the video description, but mostly based on the hairstyles.) It’s interesting to see the process and the mechanical aptitude it took to create the machines, especially with the weights and measures. The level of complexity and number of steps involved can make you wonder how we ever figured it all out, but thankfully we did!

Current cocoa production follows the same basic process through harvesting, roasting, extracting cocoa butter, and grinding of cocoa cakes into powder. And, like any manufacturing process, there are sure to be applications which demand unique solutions. This is where a recent application took place for an EXAIR end user.

Not shown in the video above is a cooling process for the cocoa powder. During the cooling process the powder is transferred through a carriage system resembling a radiator without the fins. Inside the carriage system cocoa powder can accumulate in the 180° bends, and the build-up over time can stop material flow. So, these bends are serviced as part of a regular preventative maintenance program.

The end user was looking for a way to extend the service interval length, hoping to find a solution to target the build-up areas in the 180° bends. The current setup requires manual cleaning every 15 days of operation. Modification of the existing setup is possible, provided it increases the time between maintenance procedures.

The solution we devised is a series of 316 stainless steel Super Air Nozzles, fed into the curves of the cooling carriage to prevent accumulation of the cocoa powder. The solution agitates any accumulating cocoa, removing the build-up and greatly extending the time between service intervals.

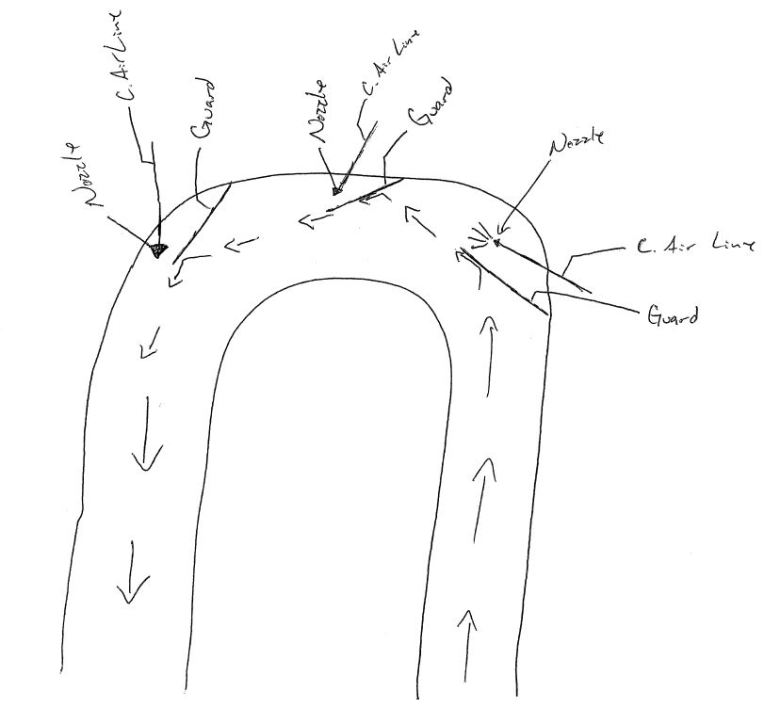

This solution can be implemented in one of two ways; either through periodic entry of the nozzles into the cooling carriage (a somewhat difficult solution to implement), or through permanent installation with guarding in place to protect the nozzles (even powders can deteriorate a material with direct contact over time). A (very) crude representation of the permanent installation is shown below.

To install the nozzles into the curves of the cooling carriage, holes must be drilled into the curves. Sealed bulkhead fittings can be installed into the holes, and the necessary compressed air lines can be fed through the sealed bulkhead fittings. This will allow installation of the air nozzles in the needed locations.

The final detail left to be sorted in this application was the exact model Super Air Nozzle to be used. The force requirement to dislodge the cocoa is highly specific and ultimately unknown, so we focused on a solution with what we deemed adequate force at an 80 PSIG operating pressure. We chose a series of 1101SS Super Air Nozzles, remembering we can always reduce force and compressed air consumption through pressure regulation if needed.

We were happy to help implement a solution to provide the needed results with the most efficient use of compressed air. After all, that’s what we do at EXAIR. We help our customers find the most suitable, most efficient solutions for their applications.

Distribuidor:

Tecmer,Lda

Tel:+351 932308640

Email:geral@tecmer.pt

Comentários

Enviar um comentário