1

Consider why you might need a flow meter. Common applications for a flowmeter might be monitoring the amount of fluid travelling through a pipe/ vessel in real-time or monitoring and controlling the total throughput volume (totalising). If a simple, one-off test is all that is required, a container to flow the liquid into, a set of scales and a stopwatch may give the accuracy needed. Similarly, flow rate could be estimated by using a simple float in a tapered tube, but this would entail the inconvenience of constant local observation. Some companies hire flowmeters and this could be an economic option for short term monitoring applications. A flowmeter offers an accurate, configurable solution which can monitor, record and be used as a method of control with minimal attention once programmed.

2

Consider the total life cost of the installation. Initial purchase price is only one aspect of the costs of running a flowmeter. A simple turbine will be inexpensive to purchase and install but the true costs may need to be considered over several years of operation. How often will your production line have to be down while that simple turbine is being re-calibrated? It may well be that a non-intrusive solid state flow meter will be more cost effective in the long term despite the initial financial outlay. In situations where a consumer product, with a design life of only a few thousand hours, incorporates a flowmeter - a more inexpensive device would be appropriate. It is important to remember that flowmeter selection is part of your overall project design and costing.

9

10

Consider why you might need a flow meter. Common applications for a flowmeter might be monitoring the amount of fluid travelling through a pipe/ vessel in real-time or monitoring and controlling the total throughput volume (totalising). If a simple, one-off test is all that is required, a container to flow the liquid into, a set of scales and a stopwatch may give the accuracy needed. Similarly, flow rate could be estimated by using a simple float in a tapered tube, but this would entail the inconvenience of constant local observation. Some companies hire flowmeters and this could be an economic option for short term monitoring applications. A flowmeter offers an accurate, configurable solution which can monitor, record and be used as a method of control with minimal attention once programmed.

2

Consider the total life cost of the installation. Initial purchase price is only one aspect of the costs of running a flowmeter. A simple turbine will be inexpensive to purchase and install but the true costs may need to be considered over several years of operation. How often will your production line have to be down while that simple turbine is being re-calibrated? It may well be that a non-intrusive solid state flow meter will be more cost effective in the long term despite the initial financial outlay. In situations where a consumer product, with a design life of only a few thousand hours, incorporates a flowmeter - a more inexpensive device would be appropriate. It is important to remember that flowmeter selection is part of your overall project design and costing.

3

Consider the operating parameters. The flowmeter selection will, of course, depend on flow rate, line pressure, temperature, accuracy requirement and ease of use. In addition, it is likely to be important that you know how your fluid behaves under all anticipated conditions. 4Consider the chemical compatibility. It is very important to ensure that the fluid to be measured is chemically compatible with the materials of the flowmeter. Remember to consider all of the flowmeter materials, not simply the material of the body. Typically a flowmeter consists of an O-ring, a rotor, turbine or Pelton wheel, embedded ceramic magnets, gears, bearings, etc. All of these could affect, or be affected by, the fluids they come into contact with. Check each material separately against a reputable chemical compatibility table and double check your selection with the manufacturer of the fluid you wish to measure to ensure long term durability.

e.g. Plastics Chemical Compatibility Chart http://www.plasticsintl.com/plastics_chemical_resistence_chart.html

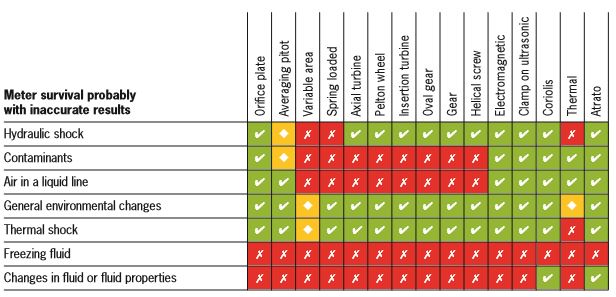

5

Consider all system parameters when making your selection. The selection of the most appropriate flowmeter will also depend on the system it is intended to be a part of. Will there be hydraulic shocks? Can the flow exceed the design rate? Is the temperature stable? Does the process require air blown through the system? Is the line cleaned in place?

If there likely to be a change in process which would require a higher or lower flow range, could this be met with a single wide ranging meter now? Awareness and consideration of the possible extremes of your overall system could save much inconvenience and expense later.

6

Go online and review available information. There is a vast amount of information about flow meters on the web, a majority of it is useful and only a minority of it misinformation. See what other people in your industry sector have done, look at manufacturer’s sites and published reports. It may be that someone has had similar requirements and solved similar issues to your own.

7

Contact several possible suppliers. There are some organisations who will simply sell you a flowmeter. There are others who will discuss your application and consult with you on your project requirements before suggesting an optimal flowmeter that meets both your operational and financial goals. If possible use a reputable supplier with a recognised quality system and an internationally recognised, traceable calibration system calibration system. This will ensure that they can provide evidence of a high level of after care service and knowledgeable support.”

8

Compare technologies pragmatically. After shopping around, it is likely that you will have been offered several technological solutions to your flow metering application - consider each one carefully. In comparing proposed technological solutions you are aiming to match a flowmeter to your operating parameters, its cost of ownership, ease of use and the level of support it may require. For example for measuring a bespoke fluid at low flow rates - ultrasonic, Coriolis, electromagnetic or perhaps even thermal flow metering may all be viable technologies. Coriolis will give you the best accuracy but can be expensive. Electromagnetic might be appropriate but is dependent on the fluid’s conductivity; and thermal will have a slow response time and poor accuracy. For many applications, and low-flow in particular, ultrasonic may offer the best combination of price, performance and ease-of-use.

9

Follow flowmeter installation instructions carefully. It is important to follow the manufacturer’s installation instructions carefully to eliminate teething problems and to ensure optimal results. Always use good instrument practice with the electrical connections. For example if you are installing a positive displacement meter the manufacturer is likely to suggest that a dummy section of pipe is installed in place of the flowmeter while the system is commissioned. It is very important that you do this. Quite often with a new installation debris will be caught somewhere in the system and even with a filter immediately before the flowmeter the device is not safe as debris in the downstream line could fall back into a positive displacement meters mechanism. Ensure the system is thoroughly flushed at maximum flow. Check that all the other components in the system working correctly, including non-return valves, pumps and isolation valves. Careful installation can eliminate many potential ‘teething’ troubles.

10

Some simple checks before calling your supplier out about a faulty meter. The author is sure he is not alone in having travelled hundreds of miles only to switch on a power supply of a ”faulty” meter which is “not responding to flow”. Is the installation wired correctly? Is any secondary instrumentation compatible and is it configured correctly? Are the cables numbered correctly? By their nature, flowmeters are checked and certified before dispatch and it is extremely rare for them to malfunction straight out of the box.

If problems occur during commissioning always check the fundamentals first. 1. Is the flowmeter/instrument the optimal one for the installation? 2. Is the power connected to the meter and the instrument, is it the correct specification and turned on? 3. Is the pump running and are the appropriate valves open? 4. Is the instrument set/wired correctly? ( input port, pulse type, frequency span, units etc.) 5. Where possible check the output from the flowmeter with an oscilloscope or other suitable test instrumentation before proceeding 6. Was the line flushed prior to installing the meter, could debris be in the meter? 7. When you started the pump or opened the valves did you increase flow slowly to prevent air flow through damage?

Comentários

Enviar um comentário